Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

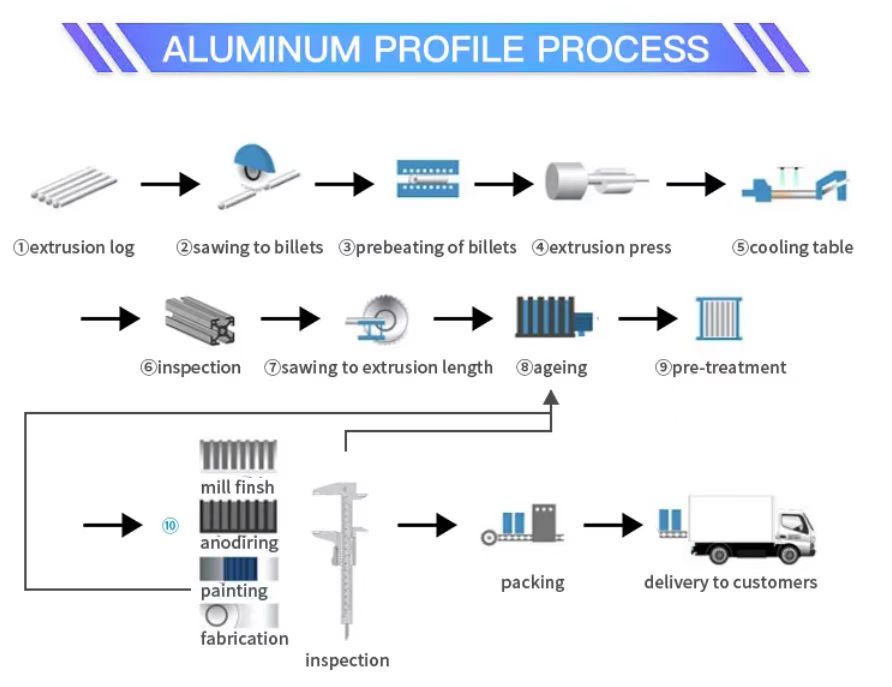

Aluminum Extrusion is the process of putting aluminum alloy into the extrusion cylinder and applying certain pressure to make it flow out of the specific die hole to obtain the required section shape and size. This method has low cost, high efficiency and simple operation. It occupies a considerable proportion in the industrial development and production management system of modern enterprises, making aluminum profiles an important basic research material in China's national economy. The extrusion of aluminum profiles shall be carried out according to the following process flow:

Preparation before aluminum extrusion:

Check the fuel system? Check the pneumatic system? Check wiring and power supply? Check the water circulation system? Check the number of aluminum bars and Mold model.After aging, it can be discharged. In the cooling stage, it can be cooled naturally or through cooling fans. So far, the staff of the extrusion enterprise has completed the extrusion of aluminum profiles with qualified appearance design quality and shape and size.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.